Gear wheels according to drawing

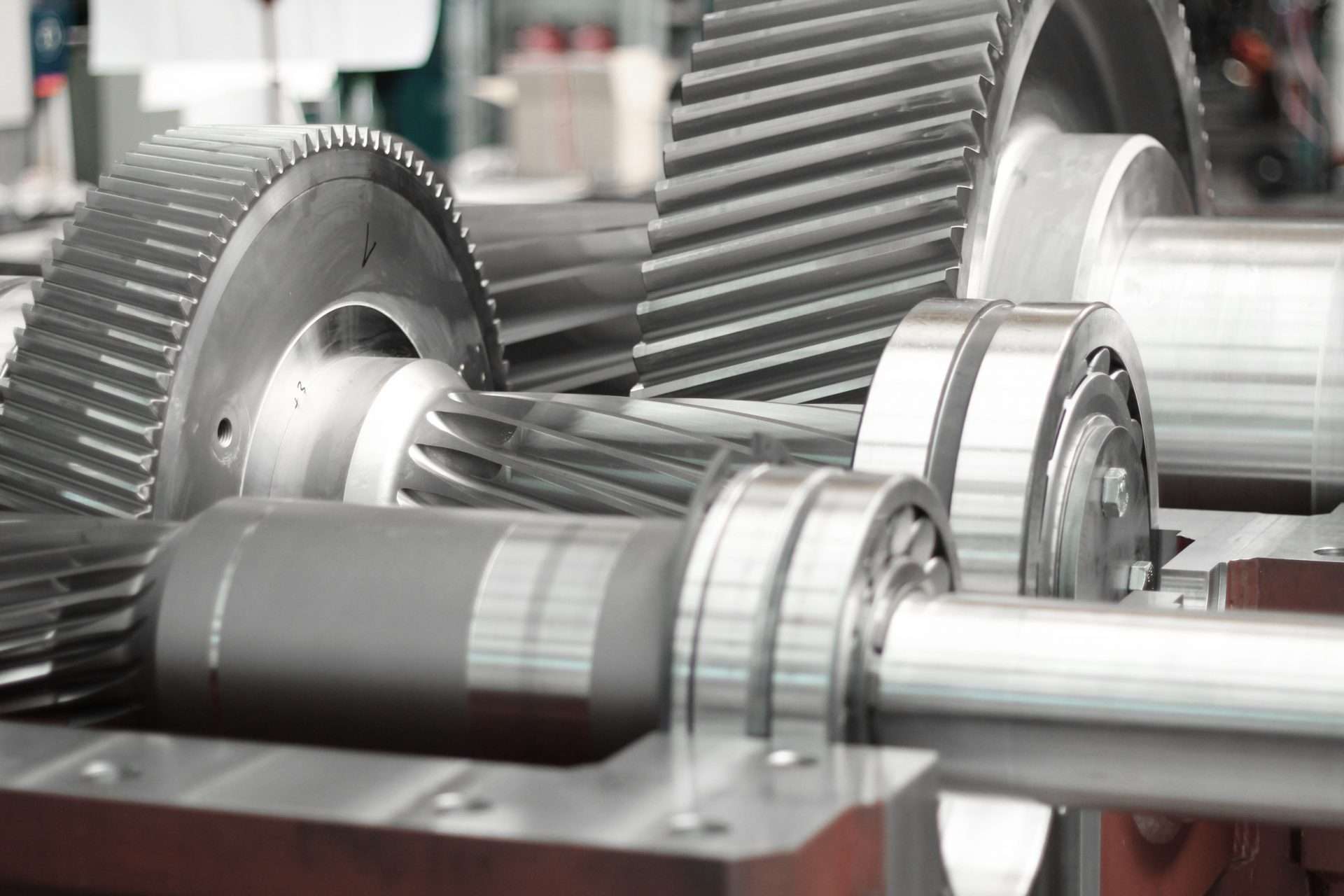

We manufacture milled and shaped teeth and, with more than 40 years of experience in tooth flank grinding, we also manufacture ground, straight, helical, double helical, internal and external teeth.

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-24

Tooth width: ø100-1800 x L 450 mm

| Process | Max. Dimensions in mm |

|---|---|

| Horizontal turning | Ø1350 x 4000 |

| Vertical turning | Ø2000 x 1000 |

| Horizontal milling | 1600 x 800 x 800 |

| Key slotting | 100 x 800 length |

| Gear hobbing | Ø1650 x 1200, Module 1-36 |

| Gear shaping | Ø800 x 200, Module 1-12 |

| Cylindrical grinding – inner | Ø1200 x 800 |

| Cylindrical grinding – outer | Ø1000 x 4000 |

| Gear grinding – inner | Ø100-Ø1800 x 450, Module 1-24 |

| Gear grinding – outer | Ø2000 x 1400, Module 1-45 |

| Gear profile measurement | Ø2000 x 1200 |

| Grinding burns, Nitral etching | Ø1450 |

| Common testing and measuring methods (e.g. MT, spectral analysis, hardness and roughness measurement) |