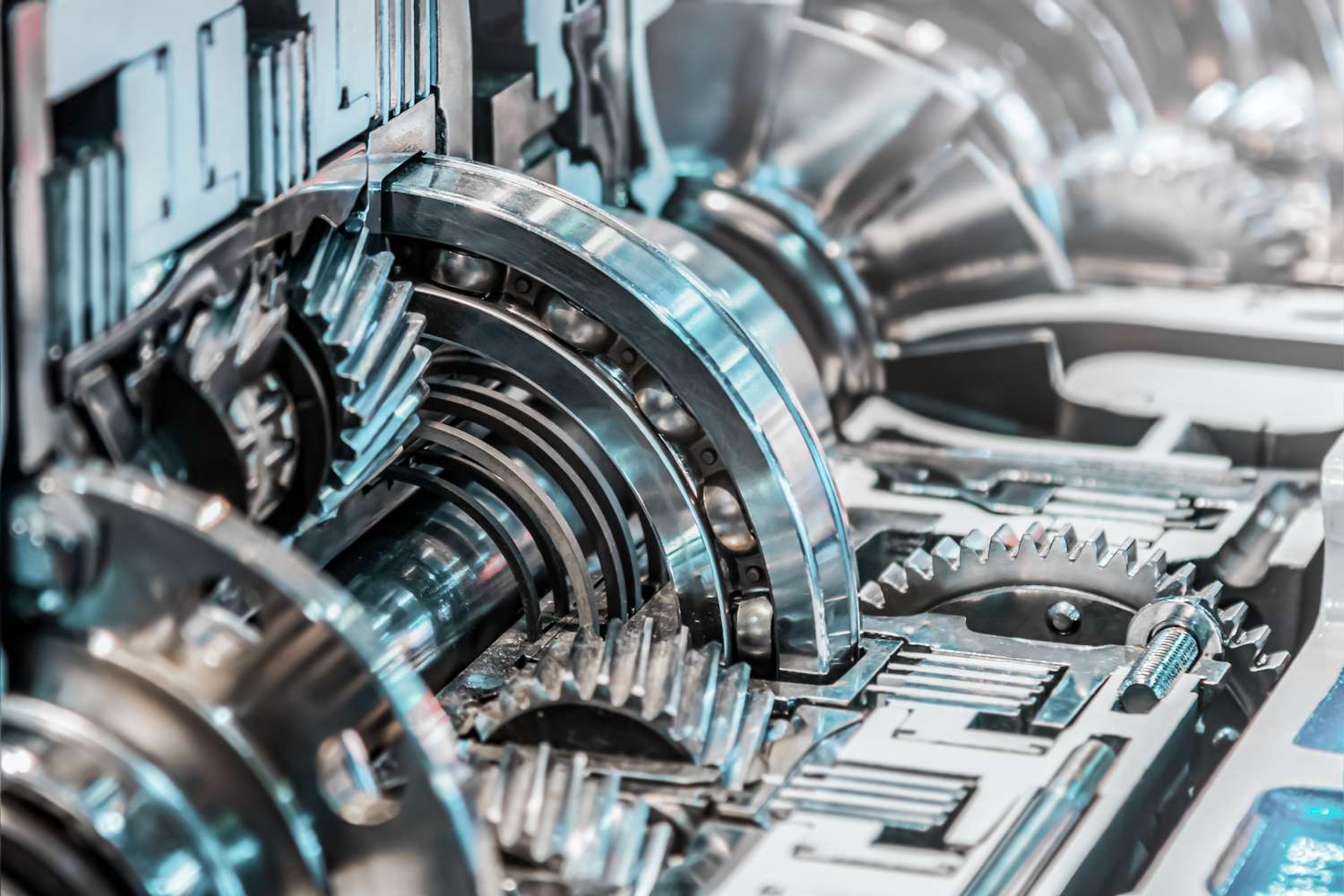

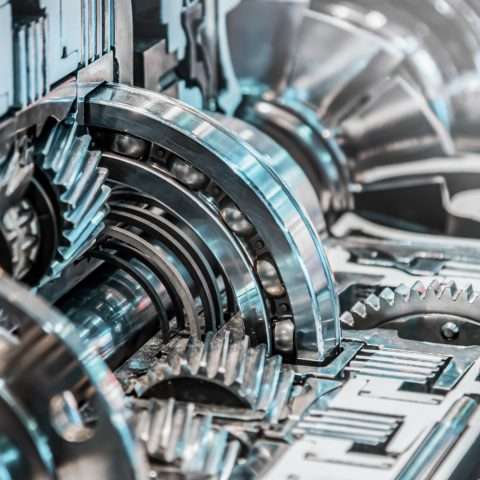

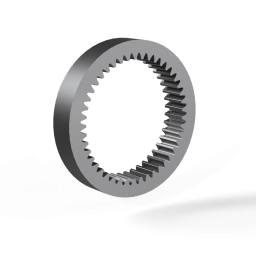

Gear wheels according to sample

With our 60 years of experience in a wide range of drive applications and with over 2000 different gear cutting tools, we can produce an almost identical duplicate to your sample with a high degree of probability.

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-24

Tooth width: ø100-1800 x L 450 mm

| Process | Max. Dimensions in mm |

|---|---|

| Horizontal turning | Ø1350 x 4000 |

| Vertical turning | Ø2000 x 1000 |

| Horizontal milling | 1600 x 800 x 800 |

| Key slotting | 100 x 800 length |

| Gear hobbing | Ø1650 x 1200, Module 1-36 |

| Gear shaping | Ø800 x 200, Module 1-12 |

| Cylindrical grinding – inner | Ø1200 x 800 |

| Cylindrical grinding – outer | Ø1000 x 4000 |

| Gear grinding – inner | Ø100-Ø1800 x 450, Module 1-24 |

| Gear grinding – outer | Ø2000 x 1400, Module 1-45 |

| Gear profile measurement | Ø2000 x 1200 |

| Grinding burns, Nitral etching | Ø1450 |

| Common testing and measuring methods (e.g. MT, spectral analysis, hardness and roughness measurement) |