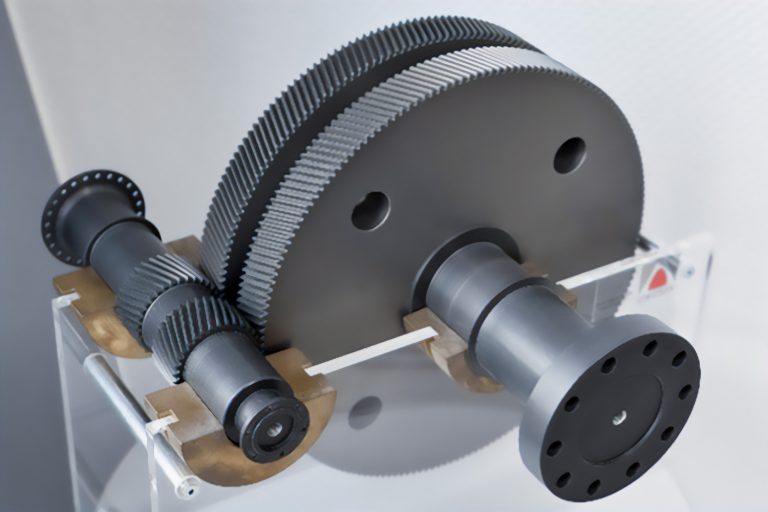

With over 2000 different gear cutting tools and more than 70 years of experience, we manufacture your component with the highest precision according to drawings or samples. Spare parts for gearboxes from Bosch Rexroth (Lohmann & Stolterfoth), Flender, Hansen, Jahnel-Kestermann (JaKe), SEW, Voith and Zollern are just a few examples of our production capabilities.

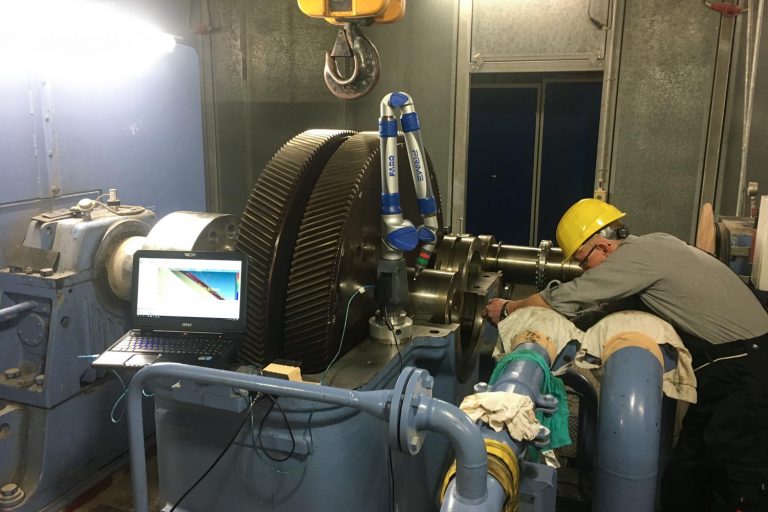

The manufacturing of components for turbo gearboxes is one of our areas of expertise and requires a high level of precision in every single step of its process. We are happy to inspect and measure your gearbox parts directly at your site. With our reverse engineering, the production of of spare parts, installation, and commissioning, we provide the complete process handled by a single source.

Gear wheels

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Pinion shafts

Module: 1-45

Tooth width: ø2000 x L 1500 mm

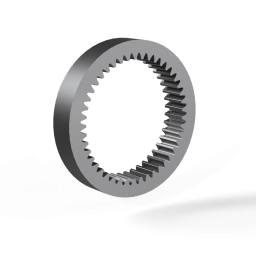

Internal gearing

Module: 1-24

Tooth width: ø100-1800 x L 450 mm

Our in-house

production capabilities

| Process | Max. Dimensions in mm |

|---|---|

| Horizontal turning | Ø1350 x 4000 |

| Vertical turning | Ø2000 x 1000 |

| Horizontal milling | 1600 x 800 x 800 |

| Key slotting | 100 x 800 length |

| Gear hobbing | Ø1650 x 1200, Module 1-36 |

| Gear shaping | Ø800 x 200, Module 1-12 |

| Cylindrical grinding – inner | Ø1200 x 800 |

| Cylindrical grinding – outer | Ø1000 x 4000 |

| Gear grinding – inner | Ø100-Ø1800 x 450, Module 1-24 |

| Gear grinding – outer | Ø2000 x 1400, Module 1-45 |

| Gear profile measurement | Ø2000 x 1200 |

| Grinding burns, Nitral etching | Ø1450 |

| Common testing and measuring methods (e.g. MT, spectral analysis, hardness and roughness measurement) |