Gear manufacturing

for marine gearboxes

Our gears will take you safely across the world's oceans.

In more than 70 years, we have acquired special expertise in the manufacture of gears for marine gearboxes and can produce your component according to drawing or sample with the highest precision. .

We work with more than ten different ship classification societies, such as ABS, DNV and Lloyds in the manufacture of components for marine gearboxes. Our many years of experience enable us to deliver even large components in the shortest possible time, in order to minimise your downtime costs. For example, we supplied a hardened gear wheel measuring around 1500 mm for the main drive of a special tanker within eight weeks. During this time, we carried out the reverse engineering, including the calculation, approval and final acceptance by a ship classification society, manufactured a forged part weighing over 5 tons and carried out the machining and heat treatment.

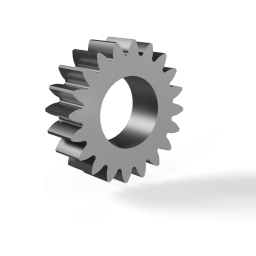

Module: 1-45

Tooth width: ø2000 x L 1500 mm

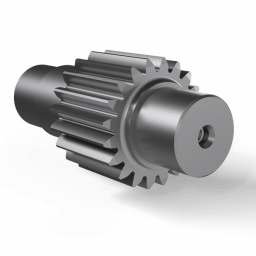

Module: 1-45

Tooth width: ø2000 x L 1500 mm

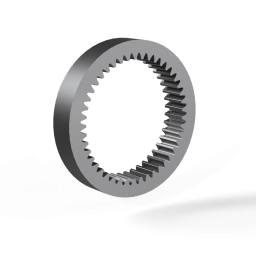

Module: 1-24

Tooth width: ø100-1800 x L 450 mm

| Process | Max. Dimensions in mm |

|---|---|

| Horizontal turning | Ø1350 x 4000 |

| Vertical turning | Ø2000 x 1000 |

| Horizontal milling | 1600 x 800 x 800 |

| Key slotting | 100 x 800 length |

| Gear hobbing | Ø1650 x 1200, Module 1-36 |

| Gear shaping | Ø800 x 200, Module 1-12 |

| Cylindrical grinding – internal | Ø1200 x 800 |

| Cylindrical grinding – external | Ø1000 x 4000 |

| Gear grinding – internal | Ø100-Ø1800 x 450, Module 1-24 |

| Gear grinding – external | Ø2000 x 1400, Module 1-45 |

| Gear profile measurement | Ø2000 x 1500 |

| Grinding burns, Nitral etching | Ø1450 |

| Hofmann RO 7000 portable concentricity/runout test system | |

| Common testing and measuring methods (e.g. MT, spectral analysis, hardness and roughness measurement) |