Gear manufacturing

for mining technology

Our gear components are used worldwide for conveying, lifting and transporting.

Precise manufacturing skills and specialized knowledge are required to produce gears for mining technology. Through years of experience we have acquired both. Replacement parts for Eickhoff and Jahnel Kestermann (JaKe) are only one aspect of what we offer.

Our company was founded in the 1950’s as a service provider to the mining industry. Since then, we have supplied all major mining equipment manufacturers with high quality gear components. Today, we primarily produce parts for export around the world.

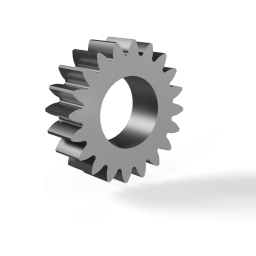

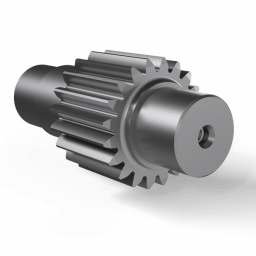

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-45

Tooth width: ø2000 x L 1500 mm

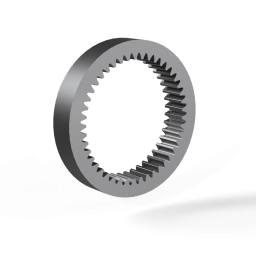

Module: 1-24

Tooth width: ø100-1800 x L 450 mm

| Process | Max. Dimensions in mm |

|---|---|

| Horizontal turning | Ø1350 x 4000 |

| Vertical turning | Ø2000 x 1000 |

| Horizontal milling | 1600 x 800 x 800 |

| Key slotting | 100 x 800 length |

| Gear hobbing | Ø1650 x 1200, Module 1-36 |

| Gear shaping | Ø800 x 200, Module 1-12 |

| Cylindrical grinding – inner | Ø1200 x 800 |

| Cylindrical grinding – outer | Ø1000 x 4000 |

| Gear grinding – inner | Ø100-Ø1800 x 450, Module 1-24 |

| Gear grinding – outer | Ø2000 x 1400, Module 1-45 |

| Gear profile measurement | Ø2000 x 1200 |

| Grinding burns, Nitral etching | Ø1450 |

| Common testing and measuring methods (e.g. MT, spectral analysis, hardness and roughness measurement) |