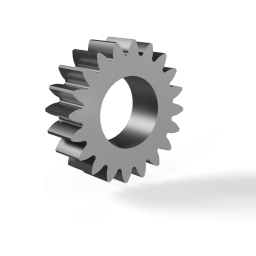

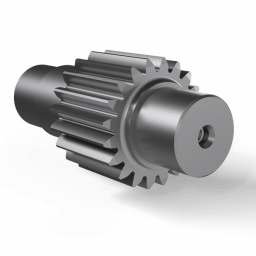

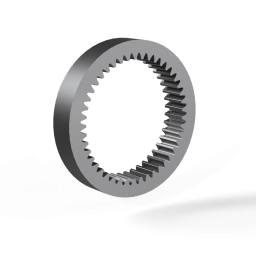

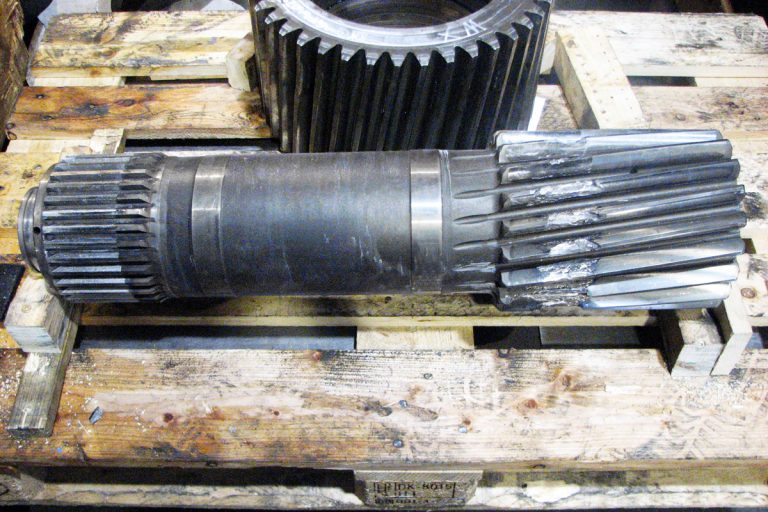

Gear wheel manufacturing

for wind turbines

Experience. Know-how. Precision. Thousands of wind turbines worldwide work with our gear wheels. We are your partner for the manufacture of customized spare parts for your gearboxes, whether production according to drawings, samples, reverse engineering or regrinding.