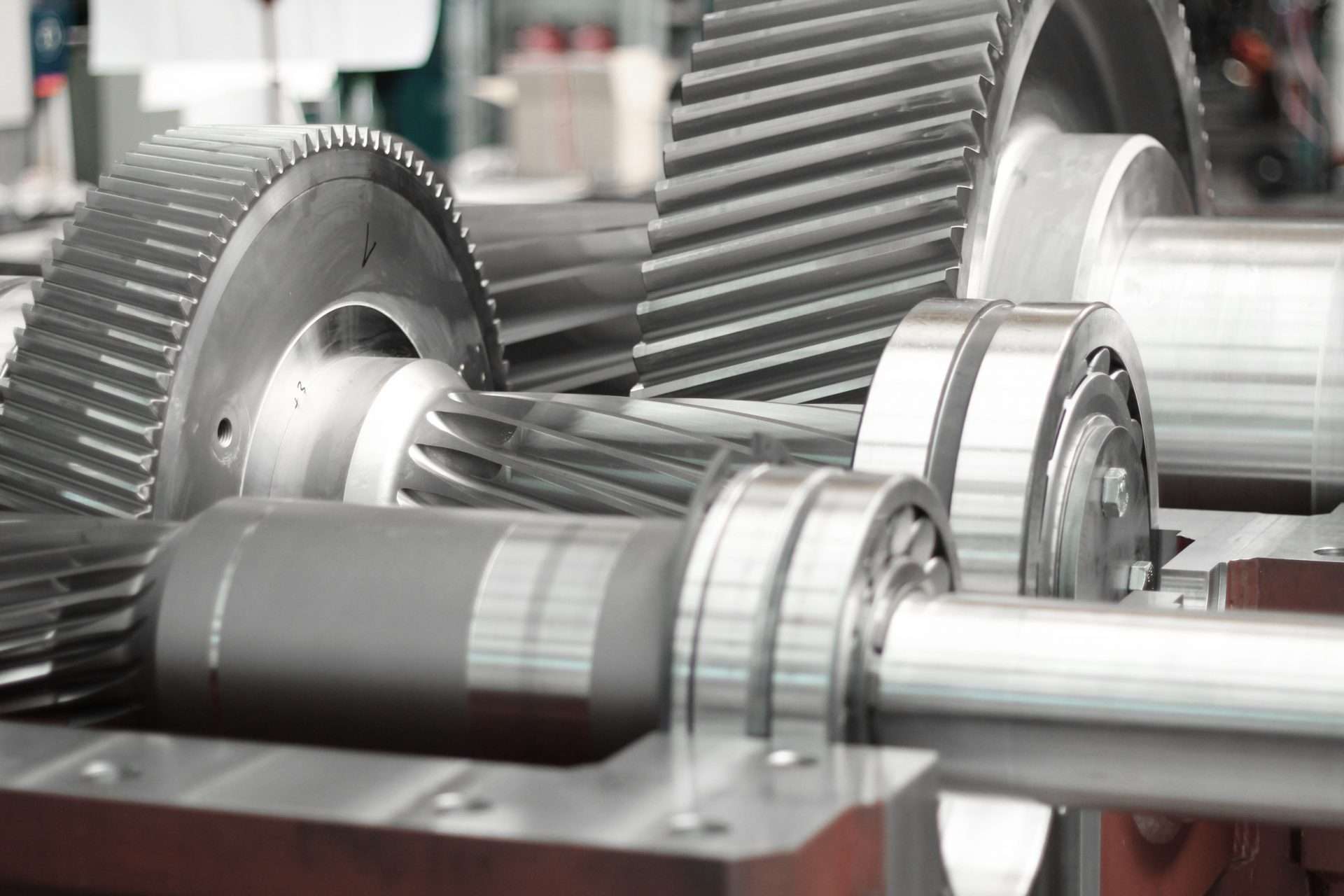

Our manufacturing capabilities

We use the latest technologies and many years of experience to manufacture high-precision gearing components. Our core competence lies in the machining of tooth flanks using grinding technology.

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-45

Tooth width: ø2000 x L 1500 mm

Module: 1-24

Tooth width: ø100-1800 x L 450 mm

| Process | Max. Dimensions in mm |

|---|---|

| Horizontal turning | Ø1350 x 4000 |

| Vertical turning | Ø2000 x 1000 |

| Horizontal milling | 1600 x 800 x 800 |

| Key slotting | 100 x 800 length |

| Gear hobbing | Ø1650 x 1200, Module 1-36 |

| Gear shaping | Ø800 x 200, Module 1-12 |

| Cylindrical grinding – internal | Ø1200 x 800 |

| Cylindrical grinding – external | Ø1000 x 4000 |

| Gear grinding – internal | Ø100-Ø1800 x 450, Module 1-24 |

| Gear grinding – external | Ø2000 x 1400, Module 1-45 |

| Gear profile measurement | Ø2000 x 1500 |

| Grinding burns, Nitral etching | Ø1450 |

| Hofmann RO 7000 portable concentricity/runout test system | |

| Common testing and measuring methods (e.g. MT, spectral analysis, hardness and roughness measurement) |